Goals and Objectives:

The goal of this lab was to learn and perform network analysis to figure out the economic impact of trucking sand to and from sand mines to rail road terminals. Per usual for the class, Trempealeau County has a focus. A script was created first to select the mines that met the requirements. Then network analysis was performed to figure the best route for each mine to its closest terminal. From there I figured with the truck routes and estimated cost per mile I determined a hypothetical economic impact on the roads in each county for mining in Wisconsin. Much of this was done using model builder.

Methods:

The first part of this lab was to create a script in order to select the suitable mines, you can find more details below in Post 2, or click here.

First I connected to ESRI's originalrawdata2013\streetmap_na\data and added the "streets" data to ArcMap. I also added the rail terminal data and mines terminal data provided by my professor. I had to select only the terminals that strictly had RAIL in the MODE_TYPE field, ensuring that none used any other form of transportation. Then using the network analysis toolbar and extension I set up a closest facility layer and set the mines as the "incidents" and the rail terminals as "facilities," then solved for closest facility.

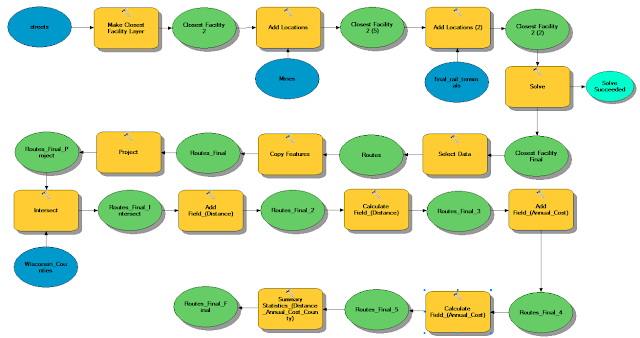

After deleting the address field in my mines feature class (it causes a problem in model builder) I opened up model builder to create a data flow model, seen in Figure A. First I added streets to the Make Closest Facility layer tool and set it to "Travel To Facility," then using the Add Locations tool I added mines and final rail terminals. After adding the Solve tool, I ran the model. Using the Select Data tool and Copy Features tool I now have my best route in my geodatabase.

Everything from here on is done to determine the total distance traveled on the roads in each county and the cost of road maintenance annually for each county. First I projected my routes and my Wisconsin counties into the NAD 1983 HARN Transverse Mercator (meters) coordinate system, then I intersected the the routes and Wisconsin counties. Next I need used the Add Field tool to create a new field which I called Distance. Then using the Calculate Field tool I changed the distance of the routes from meters to miles using the equation [SHAPE_LENGTH] * .000621371, (1 meter = .000621371 miles). Using the Add Field tool again I created a field and named it Annual_Cost. Again using the Calculate Field tool and using the equation [Distance] *50 *2 *.022 I found the cost per year of each segment of road that was being driven on. Making assumptions our professor instructed us to use 50 as the amount of times annually that each mine trucks sand, multiplied by 2 because the trucks have to come back to the mine, and that it costs 2.2 cents each mile. The last step was to use the Summarize Statistics tool to create a table that had contained each county, and its annual miles driven by the trucks on the routes, and the annual cost.

|

| Figure A shows my workflow for the exercise created in model builder. |

Results:

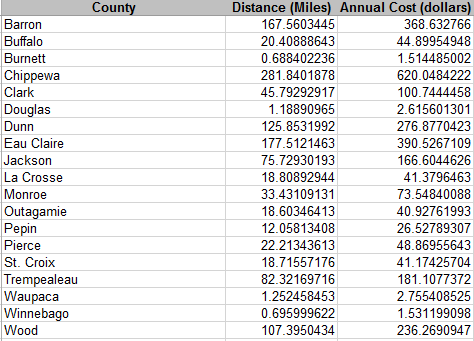

A total of 19 counties in the state of Wisconsin have sand mines that fit the criteria. The roads in these counties are affected by the trucking of sand, some worse than others, in terms of hypothetical annual cost. Using network analysis I was able to see how often the roads were traveled and although the numbers and dollars are speculations, that does not mean that this is meaningless because it still shows which states and roads are seeing more travel than others.

|

| Figure B shows the total distance the trucks traveled and the annual cost for each of the 19 counties. |

|

| Figure C shows the truck mileage per county. Due to county lines Waupaca, Winnebago, and Burnett have very little miles. Much in contrast to Chippewa and Eau Claire counties. |

|

| Figure D shows the annual costs each county would spend to repair the roads. Chippewa county would spend nearly double the next closest, Eau Claire County. |

|

| Figure D shows the locations of mines, rail terminals, and the truck routes. The counties scale from light to dark brown, lower annual cost to higher annual cost respectively. |

Discussion:

The costs on average were less than I had expected, but simultaneously I did not expect to have some values be so low, Burnett, Douglass, Waupaca, and Winnebago counties. These costs while they may be reflective, could be wildly inaccurate because we assumed 50 trips per year, some mines may do more and some may do less. We also assumed the cost to be 2.2 cents per mile, this may increase or decrease as the economic state of Wisconsin shifts. We also did not bring in to consideration the type of roads, because some types roads wither more easily than others due to their make up.

Another fallacy with our accuracy is that our network analysis techniques only calculate the most time efficient route from the mine to the rail, that time efficient route may not be the best route. And the data is from at least two years ago, I doubt many roads have changed, but in the last two years new roads could have been constructed that would make better pathways.

Conclusion:

I learned a lot from this exercise, most notably I learned how to do network analysis, which is a very key and integral part of GIS. I was also exposed to model builder again, I had previous but limited exposure to in in GIS 1, which was also a year ago.

Sources:

Hart, M. V., Adam, T., Schwartz, A. (2013). Transportation Impacts of Frac Sand Mining in the MAFC Region: Chippewa County Case Study. National Center for Freight & Infrastructure Research & Educatoin, White Paper Series: 2013, Retrieved November 19, 2015 from http://midamericafreight.org/wpcontent/uploads/FracSandWhitePaperDRAFT.pdf

Dr. Christina Hupy

ESRI street map USA

Wisconsin Department of Natural Resources

Dr. Christina Hupy

ESRI street map USA

Wisconsin Department of Natural Resources